Wiring a plug essentially involves stripping each cable to bare wire and then connecting the live red or brown to the plugs live terminal, neutral black or blue to neutral terminal and bare or green/yellow wire to the earth terminal.

However easy this may seem, it’s essential it’s done correctly as the consequences of mixing up wires and terminals could be deadly. Find out all you need to know about how to wire a plug below.

What Type of Plug Should You Use?

As this is a guide covering how to wire a UK plug, the plug that you should be using is a standard BS1363 rated 3-pin UK plug as seen in the image below.

Plugs such as these are used through out the UK, not only in England, but also in Scotland, Wales and Northern Ireland. Due to the close proximity, these plugs are also used in the Republic of Ireland.

On the whole, the UK 3-pin plug is regarded as one of the best and safest electrical plugs in the world as it features an integrated fuse, bottom-exit flex (to prevent pulling), extended earth pin, easy to grip plug housing and due to the 3 pins it can’t be plugged in the wrong way around.

Due to its safety reputation the standard UK plug has also been adopted by many other countries/regions, here is a selection:

- Hong Kong

- Cyprus

- Malta

- Singapore

- Malaysia

- Saudi Arabia

- Uganda

- Zambia

- Pakistan

- Nigeria

- Lebanon

- And many, many more…..

The standard UK 3-pin domestic plug

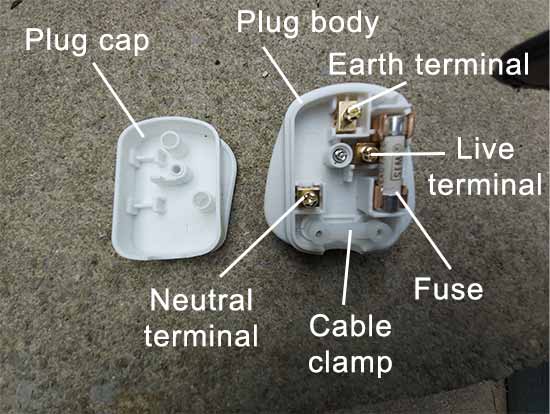

Parts of a Plug

To be totally sure of what we are referring to in the instructions below, it’s necessary to know exactly what parts make up the standard UK electrical plug, these are as follows:

- Plug Body: The body of the plug envelopes all the below objects that make up the plug and house them all safely

- Plug Cap: The plug cap covers the internals of the plug keeping everyone safe from the electrical terminals when the plug is plugged in and live

- Earth Terminal: Marked “E” inside the plug it retains the earth wire and connects to the earthing point in a standard socket. If a fault occurs it takes power away from the live and neutral, protecting the user from injury

- Live Terminal: Marked “L” inside the plug, it retains the live supply wire that runs through the fuse and then on to supply power the appliance it’s connected to

- Neutral Terminal: Marked “N” inside the plug it retains the neutral wire and connects into the neutral socket in the plug socket and returns the circuit back to the power source e.g. the consumer unit

- Fuse: UK plugs should only use ceramic HBC (high breaking capacity) fuses, not glass fuses as they cannot handle the potential heat levels cause by a fault. It’s main job is to prevent overheating of wires and appliances due to too much current draw. In the event this occurs, the wire within the fuse heats up and breaks, cutting the power. Plugs generally always come fitted with a ceramic 13amp fuse

- Cable Clamp: This grips the flex or appliance cable tightly, preventing the core live, neutral and earth wires from being pulled out and causing injury or fire

The parts of a standard UK 3-pin domestic plug

What Type of Cable Should You Use?

In almost all cases, if you’re wiring up a plug it will be to power an appliance such as a washing machine, microwave or similar and if so then it will be using 3-core appliance flex cable.

Unlike other cable such as 2.5 twin and earth which is flat and coloured grey, appliance flex is circular and normally white, however there are many other colours such as grey, black, red, yellow and blue.

The main difference between appliance flex and other types of electrical cable is that it is much more flexible, allowing you to bend and shape it around obstacles such as kitchen base units and the similar much more easily.

Generally when an appliance is supplied with its own flex, that flex will be correctly graded to carry the amount of current needed by that appliance safely, without any risk of it overheating and catching fire.

Standard 3-core appliance flex cable

Tools Needed for Wiring a Plug

To wire a UK plug you will need the following tools and products:

- Philips screwdriver

- Small flat blade screwdriver

- Wire cutters/side cutters

- Wire strippers/automatic wire strippers

- Multimeter

- Standard 3-pin UK plug

- Length of appliance flex

- Utility knife

A Note About Wire Colours in Appliance Flex

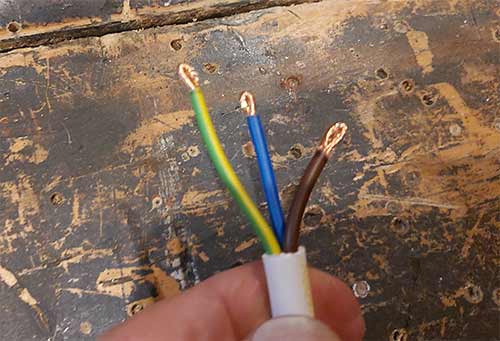

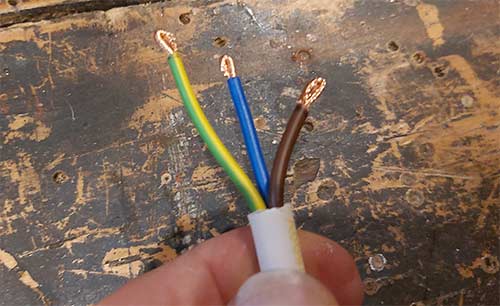

Depending on the age of appliance or flex you are wiring a plug up to will depend on what colour the 3 internal wires will be. If fairly new then it should comply with the new wire colour scheme of brown live, blue neutral and green/yellow for earth.

If the appliance or flex is old then it will probably feature the older wire colour scheme of red live, black neutral and green/yellow for earth.

In terms of older appliances using flex featuring the older wire colours, if the fuse in the plug has suddenly blown or there are other issues then it’s well worth getting the appliance fully tested just to be sure it’s safe for use.

For more information concerning wire colours see our old and new wiring colours project here.

Appliance flex featuring old wiring colours

One final point to note is that you may find only 2 wires in a piece of flex, a brown live and a blue neutral. If the appliance you’re working with is made of plastic or another insulated material then it may not be necessary to feature an earth.

Also, if the appliance is double insulated meaning although it might be made of metal it may have an additional metal outer skin or the inner and outer skins may be separated using an insulating material to the point that the dangerous live parts inside pose no threat.

One point to note is that you can only use non-earthed flex with double insulated appliances as stated by the manufacturer or appliances made from non-conductive materials where they are supplied with non-earthed flex or confirmed this is safe for use by the manufacturer.

Double insulated 4-bar light fitting

Testing Plug Fuses

When wiring up a plug, the live wire of your flex is coloured brown and goes to the live terminal on the plug. The connection is made at the end of the fuse in the plug. The live electricity has to pass through the fuse before it gets into the cable leading to your appliance. If anything is wrong, the fuse blows.

If a given appliance has stopped working the first job to do is to replace the fuse, however if you don’t have the correct ceramic fuse then the next job is to test the old one to see if it’s blown. If it has then you know there is a bigger issue somewhere that needs immediate attention.

There are a few ways to test a fuse, one is to use a car bulb and batter the other is to use a multimeter. To find out how to test a plug fuse, see our project here.

How to Wire a Plug

To wire a UK 3-pin plug, work through the following steps. For the purposes of this example we are using appliance flex with the newest wire colours of brown live, blue neutral and yellow and green earth.

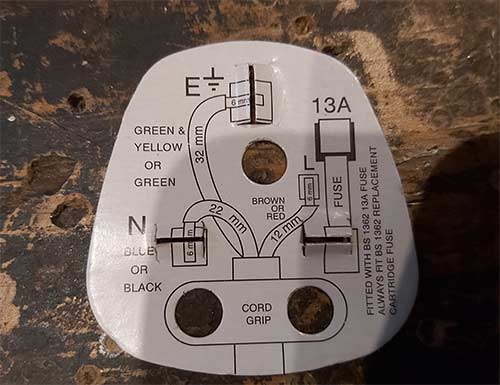

Wiring diagram for a domestic UK 3-pin plug

Step 1 – Remove Plug Cap and Cable Clamp

The first job to do is to unscrew the small screw at the centre of the underside of the plug using a Philips screwdriver.

Unscrew retaining screw

Once unscrewed, remove the screw so it doesn’t get lost and then remove the cap from the plug.

Remove plug cap and expose plug internals

Step 2 – Unscrew Cable Clamp

Using a Philips screwdriver, loosen both the small screws holding the cable clamp down. Once both loose, unscrew one totally and put it to one side.

Loosen cable clamp screws

Step 3 – Strip the Power Cord Sheath

Put the appliance flex in place in the plug and pull it up through so there is 8 – 10mm outside of the top of the body of the plug. Hold your thumb nail on the point that the flex passes through the cable clamp and use a pen to mark this point.

Mark point cable flex passes under cable clamp

Using a utility knife or other sharp knife, very carefully score through the flex cable sheath but not all the way through. You don’t want to damage the sheaths of the core wires. Once scored, bend the score backwards and forwards until it breaks all the way around and then pull it off.

Bend flex cable until the sheath breaks open

Step 4 – Cut Internal Core Wires to Length

Slip the flex cable back in place under the cable grip and spread the 3 internal core wires out to they’re respective terminals. The brown to the right terminal with the fuse, the blue to the left terminal and the yellow and green earth to the top terminal.

Pull each wire past each terminal and then use a pen to mark a point around 10mm beyond the terminal. This will mark the point where each wire needs to be stripped off.

It is also recommended that you make sure that the earth wire is the longest of all 3 wires and has a kink or loop in it. This is to ensure that if the cable clamp fails, the earth wire is the last wire to come loose, making sure that the electrical appliance continues to be earthed.

Position and mark internal core wires for stripping

Step 5 – Strip Wires and Twist Wires and Bend Them

Remove the flex and use a pair of wire strippers to strip the insulation sheath from each wire at each mark. Wire strippers or automatic wires strippers are best as you can accurately strip the sheath from each wire without cutting any of the actual wires inside.

Once stripped, twist the individual strands of each wire up tightly and then bend each wire back on itself, doubling it over.

Strip cores wires and then twist and bend them, doubling them over

Step 6 – Connect Wires to Plug Terminals

Place the flex wire back into the plug and position each core wire next to it’s respective terminal. Starting with the brown live, loosen the screw of the right hand terminal next to the fuse. Push the terminal up slightly so it’s easy to access and then push the wire into the hole, making sure it’s all the way in.

Using a small screwdriver, tighten the terminal screw all the way up ensuring it clamps the wire firmly.

Brown live wire connected to live terminal

Next, push the top earth terminal upwards and insert the stripped earth wire into the hole. Screw the terminal screw down until tight.

Connect earth wire to top earth terminal

Finally, repeat the above for the blue neutral wire. Push the left terminal up for easy access and then push the stripped end of the blue wire into the terminal and screw it up tightly.

Connect neutral blue wire to the left hand terminal

Step 7 – Test Fuse

Before putting the rest of the plug back together and using it, it’s a good idea to test the fuse. As it’s new it should be absolutely fine, but it’s best to make sure.

If you have a multimeter then you can test the fuse using that, if not then you can use a car battery and a bulb.

See the testing a fuse section above for more details on how to do this.

Testing a fuse using a multimeter

Step 8 – Tighten Cable Clamp and Replace Plug Cover

Ensure the cable clamp is positioned back over the top of the flex wire and then insert the screw back through the reverse side of the plug. Use a Philips screwdriver to tighten both screws until the wire is firmly held.

Cable clamp tightened up to hold flex wire

Finally, place the cap back on the plug and then insert the retaining screw through the base of the plug and tighten it up firmly.

Replace plug cap and tighten retaining screw

Step 9 – Test Plug

Once the plug is all wired up and back together the final job is to then plug it in and test the appliance to make sure all is working.

One point to note is that pretty much all new plugs are supplied with a paper strip over the three pins which is, most of the time, taken straight off and thrown away. This is an instruction card and gives some useful information such as the exact length the wire should be trimmed to, to enable an easy, safe connection to the plug terminal.

Paper instruction card supplied with all new plugs

Stripping Wires and Cables

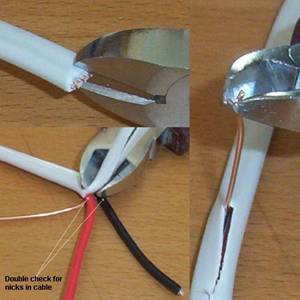

Stripping wires can be very easy but a great deal of care needs to be taken. As with most jobs and as we keep repeating, it is much easier, and safer with the right tools. Electricians will use side cutters or cable cutters for cutting and stripping cable.

Using wire cutters to strip some cable

If this is your first time wiring a plug or stripping cable, you will probably not have the ability, touch or experience to do this and a tiny little nick out of a cable, flex or wires insulation can be lethal as it will allow current to arc across wires.

The cable shown above is a 2.5mm two core and earth. First the cable is nicked through the sheath at the end. Get this nick in the middle.

Pull the sheath apart a little and you will see the bare earth wire in the centre. Clamp the wire with the side cutters gently and, holding the end of the cable in your other hand, pull the wire through the insulation. This will tear quite easily.

For those with no experience its best to use pliers for this operation rather than side cutters as shown.

Measure the connections you wish to make, add enough on to turn the wires over, do not skimp on the length.

"Stretching" cable to meet connections can mean they will pull out over time. Don’t forget your house is constantly moving through expansion and contraction. It is better to have a little more than you need folded into a socket than too little.

Fold back the bare stripped wires, doubling them over

An earth sleeve should be placed onto any bare earth wires.

Stripping flex is often more difficult than cable as it is usually more flexible because of thinner sheathing. Any nicks in flex wires must be avoided. If you do nick any core wires you will need to cut everything off and start again.

Stripping a flex cable using a purpose made cable sheath stripper

Proprietary flex strippers, wire strippers and automatic wire strippers can be bought at all DIY stores. It is well worth purchasing one of these tools as they allow accurate wire cutting and stripping and avoid any potentially dangerous nicks.

Once you know which terminal a given wire should be connected to and how to correctly strip and prepare the wires and insulation sheathing, wiring a plug is an easy job and straightforward job.

Warning: To complete electrical works you must comply with Electrical Regulations – Click here for more information.